Research and development is a key element in the collection creation process

HUGO BOSS sees research and development (R&D) as an important element in the product development process as a means of transforming a creative idea into a marketable product. This process starts with the systematic identification of fashion trends, an analysis of market and sell-through data and the evaluation of consumer feedback in order to assess customer needs as effectively as possible. In the product development process in the narrow sense, innovation is primarily expressed in the use of new types of materials, fresh patterns and finishing techniques that enhance both quality and efficiency.

Innovation and continuity go hand in hand for HUGO BOSS

As one of the leaders in the premium and luxury segment of the global apparel market, the HUGO BOSS Group places great importance on presenting fashionable, innovative products to customers season after season, in order to create purchase incentives time and again. At the same time, the customer expects HUGO BOSS to deliver products in every collection with the accustomed high product quality, perfect fit and unmistakable signature design. As a result, the focus of development at HUGO BOSS is both on exacting standards for quality, fit and consistent brand management and on outstanding and innovative design.

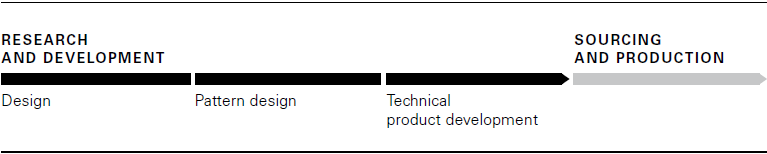

Product development process at HUGO BOSS

Because the research and development process stands at the start of the value chain, it plays a decisive role in the collection’s later success.

Creative management designs new collections influenced by numerous factors

In the first step of the product development process, creative management defines the collection statement, plans the color, theme, shape and fabric concepts and sets the targeted price points. Insights from sell-through analysis of the reference season are factored into the design process for the new collection. In order to compile information on current trends in colors and materials as well as new kinds of processing techniques at an early stage, the design departments attend specialist trade shows several times a year. In their search for new ideas, the creative teams seek inspiration from a range of fields, including architecture, design and art, but also from new technologies and socioeconomic developments. In the Fall/Winter 2014 menswear collection, for example, inspiration was derived from the Scandinavian capitals such as the new Opera House in Oslo. The collection combined architectural forms with natural fabrics and clear colors. In this first step in the product development process, the design teams also draw on the expertise of external advisors such as trend scouts to a limited extent, in order to identify fashion trends even earlier.

Pattern design and technical product development work together to turn the designs into prototypes

In a second step, the creative department hands over its sketches to the pattern design department where the feasibility of the creative ideas is initially reviewed from a tailoring perspective. The technical development department then produces prototypes from the models. With its development center in Metzingen, which has a structure reflecting industrial production operations, HUGO BOSS is able to quickly turn creative designs into prototypes and to test their suitability for inclusion in the industrial production process at an early stage. In addition, new manufacturing techniques are constantly being developed. For example, an innovative welding system was used for the development of womenswear for the first time last year. By welding individual parts of the product, it is possible to apply additional elements and therefore add fashionable highlights.

Sampling the final stage of the development process

The prototype creation stage is followed by sampling, which involves the production of a sample collection for presentation and sale to international wholesale customers. The pieces ordered are subsequently produced and sold to end customers, either through the Group’s own retail stores or the wholesale channel.

Ongoing technological enhancements secure the Group’s competitive edge

Throughout all stages, seamless collaboration of all those involved, including external suppliers and technology partners, is essential to ensure high product quality and maximize the efficiency of the research and development process. In order to keep abreast of the latest technological advances, HUGO BOSS regularly visits textile machinery fairs and tests the equipment at its development center in Metzingen. For example, a modern cutting machine was installed at the Metzingen facility last year. By optically scanning the material properties, it is able to process the patterns of even striped and checked materials precisely, quickly and completely automatically.

Innovative virtualization technology simplifies the development process

To further simplify and accelerate technical product development, the Group is increasingly using computer-based virtualization technology for shirts, jerseys, knitwear, outerwear, trousers, bodywear, blouses, dresses, suits and shoes. Virtual product development entails making digital 2D patterns of the designers’ creative ideas and then converting these to 3D simulations of the finished product. With the help of these 3D prototypes it is possible to virtually visualize different color and material variations and the use of different processing techniques. Virtual prototypes can be discussed with in-house employees involved in the process directly on the computer terminal and adjusted flexibly. This close cooperation between the development teams makes it possible to develop products not only more quickly but also less expensively and on a more sustainable basis due to the reduced need for physical prototypes. In this way, the use of 3D technology makes it possible to optimize the development process significantly.

Use of virtualization technology planned along the entire value chain

The technology is to be rolled out to all product categories and also used in the early collaboration processes with suppliers in future. A further aim is to deploy the broad range of possibilities afforded by virtualization upstream in the creative design phase and downstream in the sale of products to business partners and end customers. For instance, the technology makes it possible to present collections in showrooms worldwide to demonstrate different fabric or color variations in virtual form rather than using physical samples, significantly optimizing the use of resources.